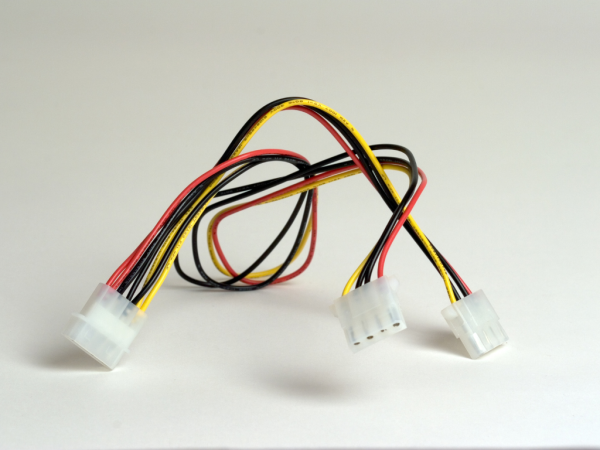

Medley, FL 33178, United States, 14th Nov 2025 – Cloom Tech, an industry-leading manufacturer of custom wire harnesses and cable assemblies, has announced the successful delivery of a specialized series of Molex cable assemblies developed for advanced electronic applications. The assemblies are designed to provide enhanced electrical performance, mechanical reliability, and long-term stability across demanding industrial environments.

The introduction of these Molex assemblies reflects Cloom Tech’s focus on precision manufacturing and tailored connectivity solutions. Each assembly is produced to support complex configurations used in automotive engineering, robotics, aerospace systems, and medical devices. Through comprehensive design validation and controlled production, the assemblies meet stringent requirements for signal integrity, environmental endurance, and component compatibility.

The production process behind the Molex assemblies emphasizes precision at every stage. Material selection, connector integration, and quality verification are coordinated through a standardized system of inspection and testing. The result is a set of wiring solutions engineered to deliver stable electrical pathways under variable operating conditions, including temperature fluctuations, vibration, and electromagnetic exposure.

“The development and delivery of Molex cable assemblies mark a strategic step toward providing reliable and adaptable connectivity solutions for high-performance electronics,” stated Ivy Zhao, Spokesperson at Cloom Tech. “Each assembly is built through a meticulous process that ensures dimensional accuracy, consistent conductivity, and compliance with applicable performance standards.”

Cloom Tech’s engineering team applies advanced assembly methods to maintain uniformity across both low-volume prototypes and large-scale production runs. Rigorous testing procedures are employed to verify insulation resistance, continuity, and mechanical strength. Each product undergoes a full quality assessment before shipment, confirming adherence to international safety and reliability benchmarks.

The Molex assemblies are designed to support critical functions in systems requiring compact, efficient, and durable interconnections. In automotive and robotics applications, the assemblies contribute to dependable signal communication between controllers, actuators, and sensors. Within the aerospace sector, they support optimized performance in weight-sensitive environments, where precision wiring is essential to operational safety. Medical equipment manufacturers benefit from the assemblies’ precision and compliance with material and electrical standards that govern life-supporting technologies.

Beyond immediate functionality, the assemblies address broader industrial needs for modularity and adaptability. By combining standard connector configurations with customized wire specifications, Cloom Tech ensures that each solution integrates seamlessly into complex system architectures. This approach supports both existing designs and next-generation electronic innovations.

Cloom Tech’s Medley, Florida facility operates under strict process controls that govern material sourcing, assembly, and inspection. The company’s quality management framework ensures traceability from design concept through to final verification. Continuous improvement initiatives are integrated into production workflows to enhance manufacturing efficiency and product consistency.

In line with the company’s focus on technical precision, the development of the Molex assemblies also reflects an understanding of emerging industry trends. Increasing automation, miniaturization, and energy efficiency have created new challenges in electronic system design, and the assemblies are positioned to meet these challenges through adaptable engineering and robust construction.

“Future initiatives will continue to advance the capabilities of cable assembly manufacturing, focusing on innovation, material optimization, and automation,” Zhao added. “As industries progress toward higher data transmission speeds and more compact designs, Cloom Tech remains committed to delivering solutions that align with these evolving technical requirements.”

The release of the Molex assemblies underscores Cloom Tech’s role as a supplier of engineered connectivity products built for long-term performance and dependability. Each project undertaken by the company integrates detailed design collaboration, precise assembly, and verified quality assurance. By maintaining strict control over each stage of production, the organization ensures consistency in output and reliability in service.

Through continuous investment in technology, training, and inspection systems, Cloom Tech strengthens its position as a trusted manufacturer within the electrical and electronic supply chain. The Molex assembly initiative reflects a commitment to developing practical, high-quality solutions for industries that depend on accurate electrical transmission and durable design integrity.

For more information about Molex cable assemblies, please contact Cloom Tech at their office located at 9251 NW 112th Ave, Medley, FL 33178, USA. To inquire further, call +1 863 434 8447 or email sales@cloomtech.com.

Media Contact

Organization: Cloom Tech

Contact Person: Ivy Zhao

Website: https://cloomtech.com/

Email: Send Email

Contact Number: +18634348447

Address:9251 NW 112th Ave

City: Medley

State: FL 33178

Country:United States

Release id:37066

The post Cloom Tech Delivers Molex Cable Assemblies for High-Performance Electronics appeared first on King Newswire. This content is provided by a third-party source.. King Newswire makes no warranties or representations in connection with it. King Newswire is a press release distribution agency and does not endorse or verify the claims made in this release. If you have any complaints or copyright concerns related to this article, please contact the company listed in the ‘Media Contact’ section

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No fortuneglobalwealth journalist was involved in the writing and production of this article.